Professional CNC Machining Supplier & Manufacturers In China | ZUERST

Precision CNC Machining Services Supplier in China

ZUERST is a leading CNC machining services supplier in China.

Our 3-axis, 4-axis, and 5-axis CNC milling, turning centers and CNC Lathe machine enable to make precise, high-quality CNC parts that fulfill your custom specifications.

With over 50 sets of CNC machines in China, AT Machining can be your ideal choice for outsourcing custom and precision CNC machining services. no matter your industry. Get your quote today.

CNC, or computer numerical control machining, is a widely used manufacturing process that uses automated, high-speed cutting tools to remove material from a metal or plastic workpiece until the desired geometry is achieved. Standard CNC machines include 3-axis, 4-axis, and 5-axis milling machines, lathes, and routers. Machines may vary in how CNC parts are cut—the workpiece may remain in place while the tool moves, the tool may remain in place while the workpiece is rotated and moved, or both the cutting tool and workpiece may move together

When a machinists receive the CAD (computer-aided design) model which is also called 3D file, they will start from programing tool paths based on the 3D file. A skilled machinist knows how to optimize the tool paths to lower CNC machining cost as well as to achieve tight tolerance. CNC machines can cut almost any material such as metal alloys, plastics, wood, stones, ceramics and more. Making custom machined parts needed for nearly every industry, including automotive, robotics, medical, aerospace, electronics and industrial. 3ERP provides CNC machining services and offers custom CNC quotes on various of materials ranging from commodity aluminum, steel, stainless steel, ABS, acetal to advanced titanium, Inconel, and engineered plastics like Teflon, PPS, PEI and PEEK.

Materials for CNC Machining Parts

Zuerst offers a wide variety of materials for custom CNC machining, plastic, and metal,

including but not limited to:

CNC plastic

What is CNC Machining?

CNC machining is a widely used manufacturing process that automates the creation of designs from metal or plastic stock using high-speed cutting tools. Standard CNC machines include 3-, 4-, and 5-axis milling machines, lathes, and routers, with variations in how parts are cut. Workpieces may be stationary while the tool moves, the tool may stay put while the workpiece is rotated and moved, or both the tool and workpiece may move in unison.

Skilled machinists program CNC machines based on CAD models to cut precise and repeatable tool paths for custom parts. CNC machining works with almost any metal or rigid plastic, making it suitable for industries from aerospace to electronics. Zuerst provides custom CNC services for over 50 materials, from commodity aluminum to advanced titanium and engineered plastics like PEEK and Ultem 2300.

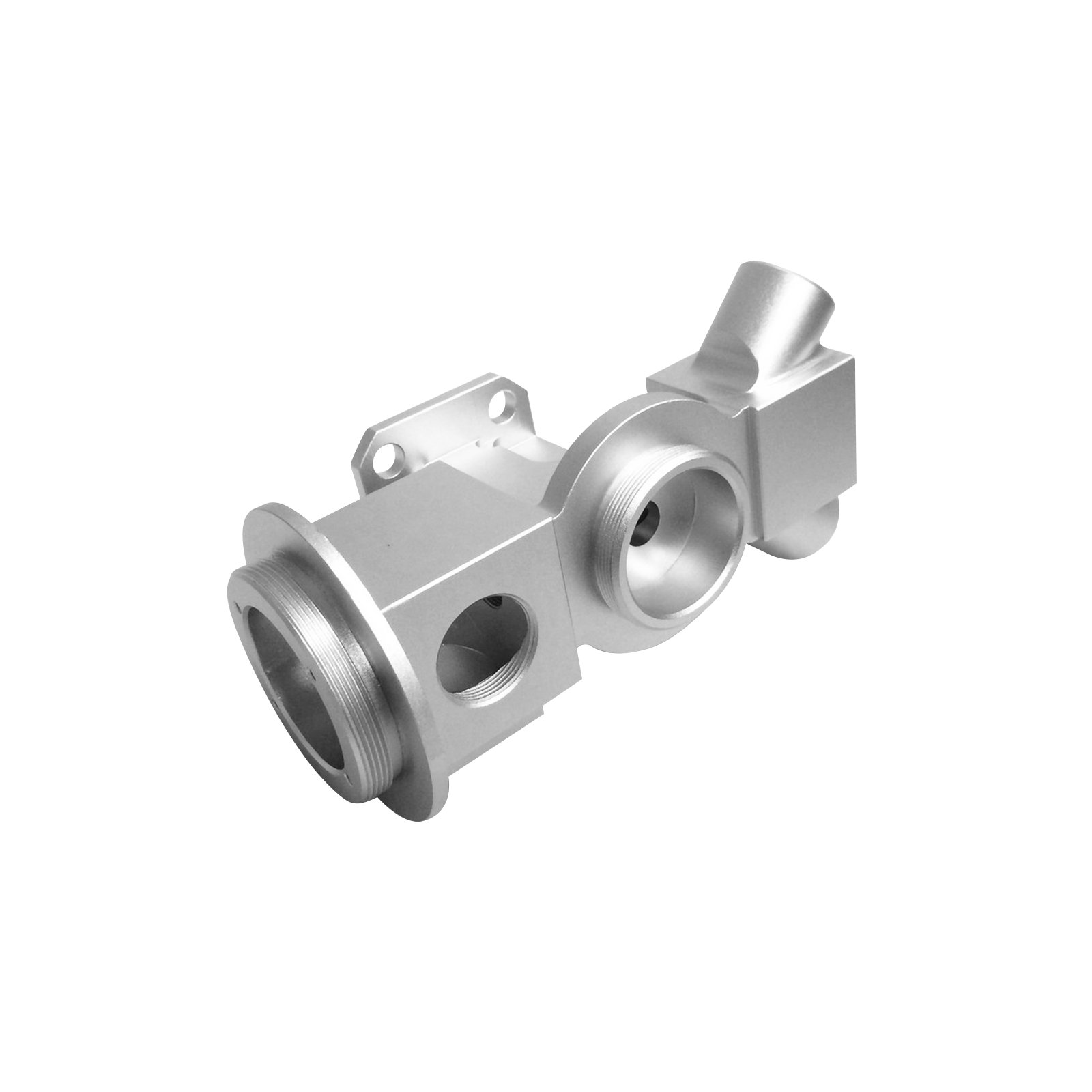

Gallery of Our CNC machining parts

CNC Machining FAQs

Why Choose ZUERST?

Experience and Expertise With over a decade of experience in CNC turning, ZUERST brings unparalleled expertise to every project. Our skilled team utilizes advanced technology to deliver precise and high-quality components, ensuring your project's success.

Customer Support Our dedicated customer support team is available 24/7 to assist you. Whether you need technical guidance or have specific project inquiries, our experts are here to provide timely and effective solutions, ensuring a smooth and efficient process from start to finish.

Get Started

Ready to begin your CNC turning project with ZUERST? Request a quote or contact us for more information. Simply upload your CAD files to receive instant feedback and pricing. Our team is here to support you every step of the way, ensuring precision and efficiency for all your CNC turning needs.

OEM

ODM

Distributor