Custom Mold Making Services Supplier & Manufacturer | ZUERST

At ZUERST, we stand out with our expertise and superior service offerings:

- Fast DFM Reports: Before production begins, we deliver a comprehensive DFM (Design for Manufacturability) report, identifying potential design issues to avoid costly delays.

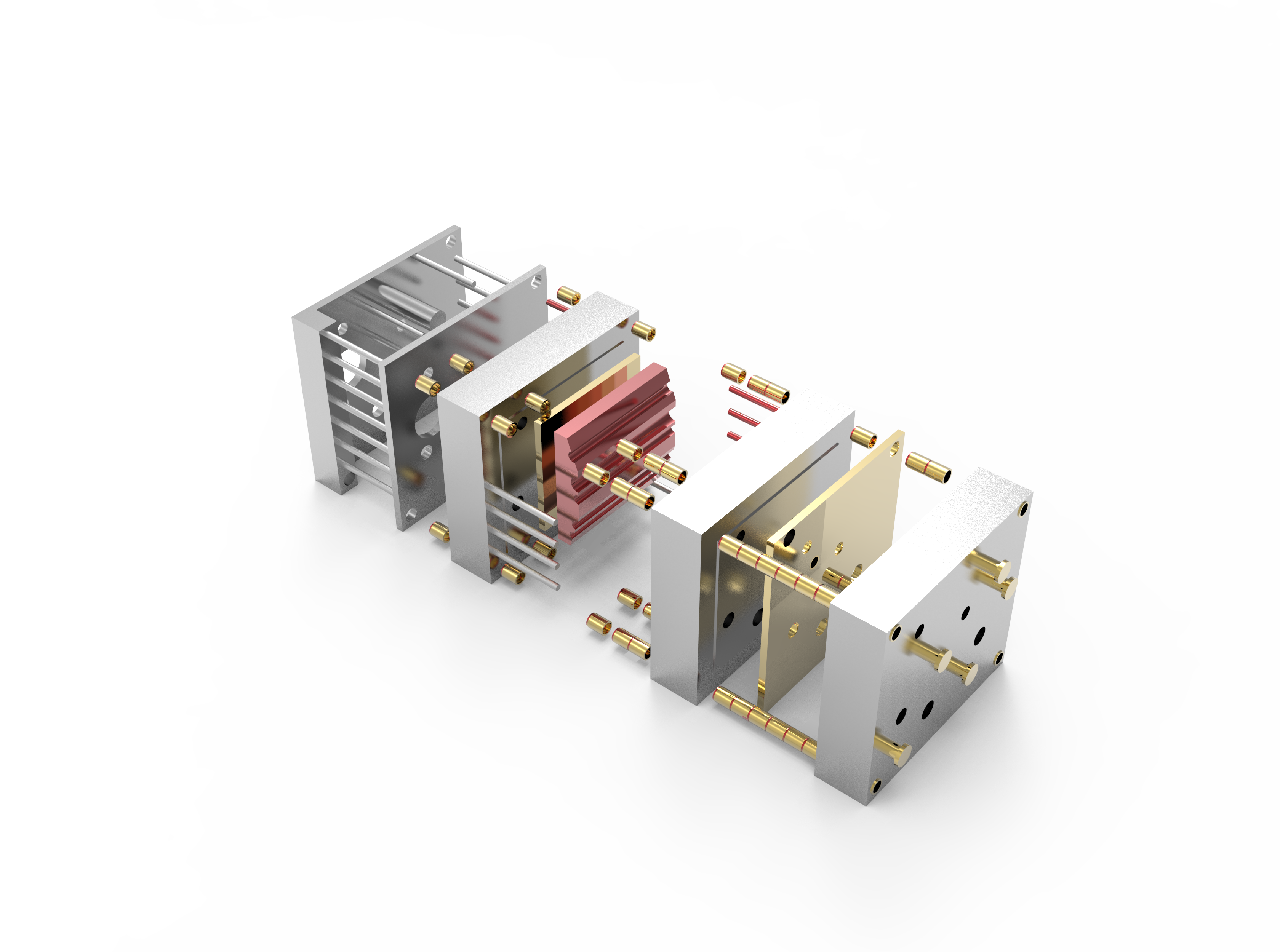

- Diverse Mold Solutions: From plastic to metal molds, we handle your entire project, ensuring seamless execution.

- Rapid Turnaround: Our advanced facilities and machining capabilities allow for fast mold production, regardless of material or complexity.

- End-to-End Services: Beyond molds, we offer injection molding and production services, providing complete parts from design to delivery.

At ZUERST, we follow a precise and efficient mold-making process to ensure high-quality results:

Why Choose ZUERST?

Experience and Expertise With over a decade of experience in CNC turning, ZUERST brings unparalleled expertise to every project. Our skilled team utilizes advanced technology to deliver precise and high-quality components, ensuring your project's success.

Customer Support Our dedicated customer support team is available 24/7 to assist you. Whether you need technical guidance or have specific project inquiries, our experts are here to provide timely and effective solutions, ensuring a smooth and efficient process from start to finish.

Get Started

Ready to begin your CNC turning project with ZUERST? Request a quote or contact us for more information. Simply upload your CAD files to receive instant feedback and pricing. Our team is here to support you every step of the way, ensuring precision and efficiency for all your CNC turning needs.

OEM

ODM

Distributor