Five Differences You Should Know About CNC Machining Parts

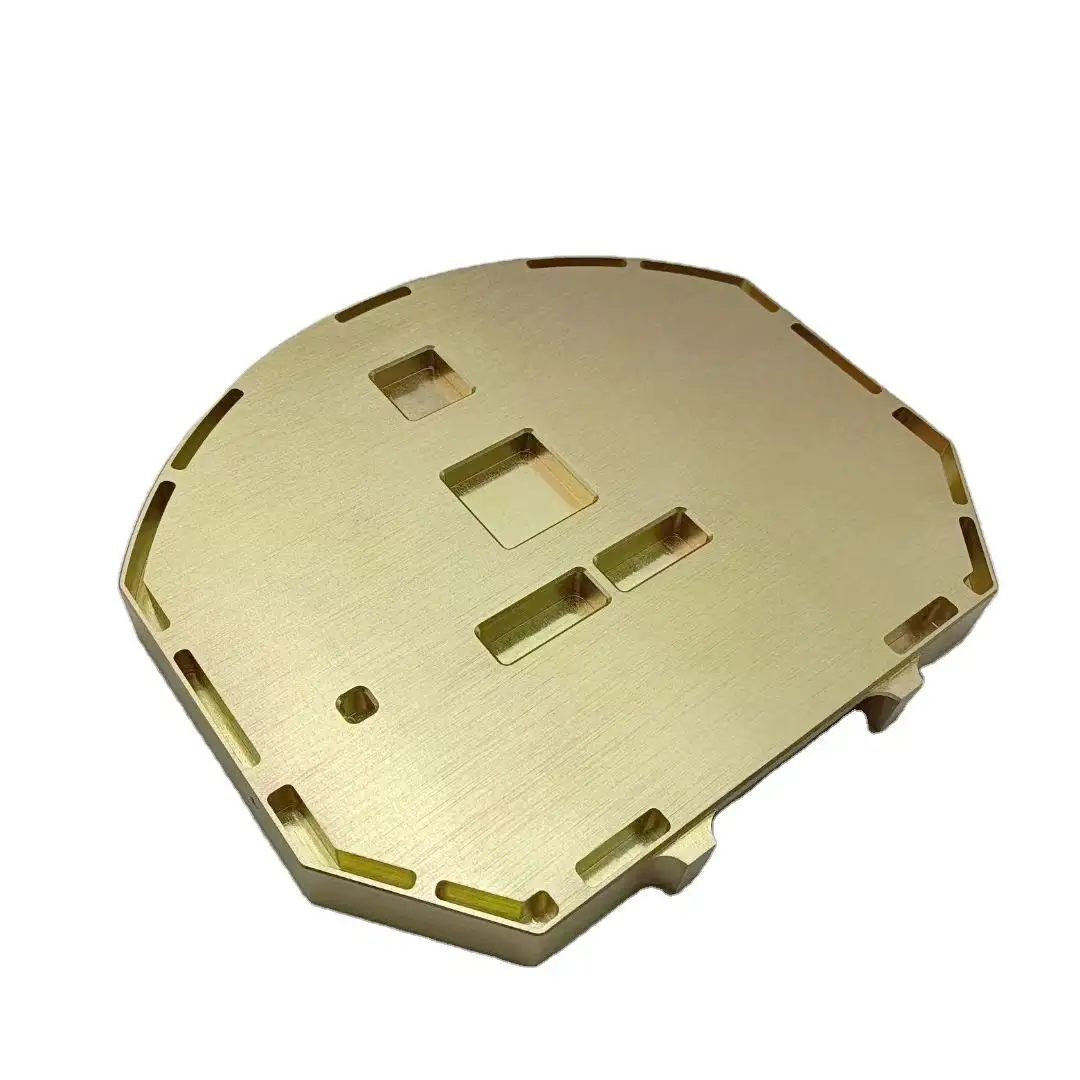

CNC machining parts are essential in various industrial applications due to their precision, repeatability, and high level of accuracy. This process involves using computer-controlled machines to shape and cut materials into the desired form. Unique challenges, such as material selection and toolpath optimization, significantly affect the efficiency and quality of the final parts. For instance, materials like titanium or superalloys require specialized techniques to address issues such as tool wear and heat generation, often necessitating advanced cooling methods and rigorous calibration processes. Adaptive control software and multi-axis machines have revolutionized CNC machining by allowing for tighter tolerances and faster cycle times. However, these technologies also require a shift in workforce skills and continuous training. Sustainable practices, such as energy-efficient coolant systems and recycled cutting fluids, further enhance the eco-friendliness of CNC machining, aligning with broader environmental concerns. Overall, CNC machining parts represent a sophisticated blend of technology, precision, and sustainability, playing a crucial role in modern manufacturing.

Latest Advancements in CNC Machining

The latest advancements in CNC machining have expanded the range of materials that can be effectively processed, including advanced composites and titanium alloys. These materials offer unique benefits such as improved strength-to-weight ratios and enhanced dimensional stability, making them essential for industries like aerospace, automotive, and medical. Managing the challenges associated with machining these advanced materials, such as heat buildup, delamination, and tool wear, has been addressed through innovative solutions like waterjet cooling, hybrid tools, and high-speed machining techniques. Automation and artificial intelligence have also improved precision, reduced downtime, and cut production costs. The integration of additive manufacturing with CNC machining offers a synergistic approach, enabling rapid prototyping and precise finishing. Advanced material testing techniques, such as X-ray CT scans, microscopic hardness testing, and tensile fatigue tests, ensure consistent properties between 3D printed and traditionally machined parts, enhancing the overall performance and reliability of final products.

Common Materials Used in CNC Machining Parts

Heres a quick guide to the most common materials used in CNC machining parts, each with its unique advantages:

- Aluminum: Known for excellent machinability and lightweight properties, making it ideal for parts requiring high precision and easy handling. Common applications include aerospace components and electronic casings.

- Steel: Offers outstanding strength and durability, making it a go-to material for heavy-duty machinery and structural parts. Its robustness ensures longevity and performance in demanding environments.

- Stainless Steel: Ideal for parts needing corrosion resistance and resistance to chemicals, with a sleek, shiny finish. Often used in medical devices and food processing equipment.

- Titanium: Known for its extreme strength-to-weight ratio and resistance to heat and corrosion, making it perfect for components in aerospace and high-temperature applications.

- Ceramic: Provides exceptional hardness and thermal conductivity, suitable for intricate and wear-resistant parts. Frequently used in precision machine components and cutting tools.

CNC Machining Tolerances and Accuracy

CNC machining tolerances and accuracy are critical for producing parts that meet precise specifications, ensuring they fit and function as required. Achieving tight tolerances involves managing various factors such as material properties, machine setup, and maintenance. Materials like stainless steel, while durable, can be challenging due to their hardness, necessitating high-speed machining techniques. Conversely, aluminum is easier to machine, with better chip evacuation and reduced tool wear, making it ideal for tight tolerances in precision applications. Advanced tools and diagnostic methods, such as CMMs and laser displacement sensors, play a key role in maintaining accuracy, while real-time monitoring systems using IoT can enhance predictive maintenance and workflow efficiency. Regular calibration and maintenance, including high-precision spindles and reliable tool changers, are essential to ensure consistent results. By balancing material selection, tooling, and operational practices, manufacturers can significantly improve the accuracy and reliability of their CNC machined parts, optimizing both the manufacturing process and the final product's performance.

Applications of CNC Machining Parts in Manufacturing

CNC machining parts play a pivotal role in modern manufacturing by ensuring precision, durability, and adaptability across various sectors. In aerospace, CNC machining is crucial for producing complex geometries and maintaining tight tolerances, essential for aircraft reliability and safety. Similarly, in the automotive sector, CNC parts contribute to enhanced performance and efficiency through the production of lightweight, high-strength components. Advanced surface treatments like anodizing aluminum enhance corrosion resistance and durability, especially in harsh aerospace environments. Integration of advanced techniques like 3D printing with CNC machining further drives innovation, optimizing costs and supply chain resilience. These advancements not only reduce environmental impact but also improve performance and reliability, marking a significant shift towards a more sustainable and efficient manufacturing landscape.

Quality Control and Testing in CNC Parts

Quality control and testing are vital in CNC parts manufacturing to ensure consistent product integrity and performance. A tiered inspection system involves initial checks during setup, ongoing inspections during machining, and final quality assurance reviews. Non-destructive testing (NDT) methods, such as ultrasonic testing and magnetic particle inspection, are crucial for identifying internal and surface defects. Advanced software integration enhances defect detection and production efficiency, while automation and artificial intelligence analyze data from previous inspections to predict defects and optimize inspection paths. Collaborative robots (cobots) assist human workers, automate tasks, and enhance precision, especially in flexible environments. Predictive maintenance, using real-time analytics and machine learning, optimizes quality assurance, ensuring equipment is always in top condition and minimizing downtime. These strategies help manufacturers adhere to strict industry standards and regulations, maintaining high-quality CNC parts and preventing production disruptions.

Conclusion

Integrating CNC machining into educational curricula significantly enhances the student experience and industry readiness. By providing hands-on learning and realistic skill development, CNC machining equips students with competencies directly applicable in the workforce. Universities face challenges such as limited budgets and instructor expertise, but effective strategies like grant funding, industry partnerships, and training programs can overcome these obstacles. Furthermore, leveraging CNC machining contributes to regional economic development through community outreach and makerspaces, fostering partnerships that support local businesses. Industry collaboration and research partnerships advance technological innovation and align educational programs with industrial needs, ensuring students are well-prepared for careers in advanced manufacturing and related fields.

OEM

ODM

Distributor